Die casting is a fairly specialised process which has developed more predominantly within the 20th century. The basic process comprises of: molten metal is poured/injected into a steel mould and via high velocity, constant and intensifying pressure (in pressure die casting) and cooling the molten metal solidifies to form a solid casting. Typically, the process itself only takes a few seconds and is a quick way of forming metal product from raw material. Die casting is suited to materials such as tin, lead, zinc, aluminium, magnesium to copper alloys and even iron alloys such as stainless steel. The main alloys utilised today in pressure die casting are aluminium, zinc and magnesium. From the early die cast machines which orientated die tools in vertical orientation to the now common standard of horizontal orientation and operation, four tie bar tensioning and fully computer controlled process stages the process has advanced throughout the years.

The industry has grown into a worldwide manufacturing machine, making components for a variety of applications, many of which will be in reach from ones self as the product application of die castings is so diverse.

Some of the benefits of high pressure die casting:

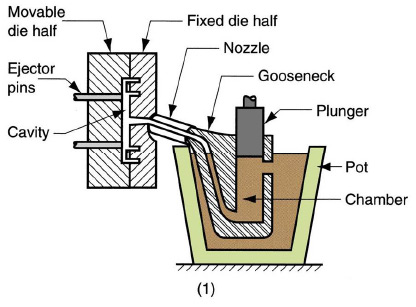

The process of hot chamber pressure die casting involves the melting of metal ingot within a furnace which is situated close/integral to the fixed half platen of the die casting machine and injection of molten metal via a submerged plunger directly through the gooseneck and nozzle and into the die tool. The gooseneck and nozzle require heating to prevent metal freezing before it gets to the die cavity, the whole heating and molten metal element of this process is where the designation hot chamber comes from. The casting shot weight is dictated by the stroke, length and diameter of the plunger as well as the sleeve/chamber size and the nozzle also plays a part which should be considered upon die design. Once the metal has solidified in the die cavity (takes only a few seconds) the moving half platen of the machine of which the moving half of the die is fixed to opens and the casting is ejected off the die face and removed from the tool. The die faces are then lubricated via a spray system, the die closes and the process cycles again.

Because of this “closed” metal melt/injection system and minimal mechanical movement hot chamber die casting can provide better economies for production. Zinc metal alloy is primarily used in hot chamber pressure die casting which has a fairly low melting point which offers further benefits for low wear on machines (pot, gooseneck, sleeve, plunger, nozzle) and also low wear on die tools (so longer tool life compared to aluminium die casting tools – subject to casting quality acceptance).

The name cold chamber comes from the process of molten metal being poured into a cold chamber/shot sleeve which is attached through the fixed half die platen to the back of the fixed half die tool. Molten metal holding/melting furnaces are typically located as close as is practical to the shot end of the die casting machine so that a manual operator or an automatic pouring ladle can extract the molten metal required for each shot/cycle with a ladle and pour the molten metal into a pouring hole within the sleeve/shot chamber. A plunger tip (which is a wearable and replaceable part, precision machined to the shot sleeve inner diameter with allowance for thermal expansion) connected to the ram of the machine pushes the molten metal through the shot chamber and into the die cavity. The die casting machine when prompted will conduct first stage to push the molten metal past the pouring hole in the sleeve. Further stages take place under increased hydraulic pressures from the ram to inject the molten metal into the die cavity. The whole process takes seconds, the quick and intensifying pressure as well as the drop in metal temperature causes the metal to solidify in the die cavity. The moving half platen of the die casting machine opens (of which the moving half of the die tool is fixed to) and ejects the solidified casting off the die face of the tool. The casting is removed, the die faces are lubricated with a spray system and then the cycle is repeated.

Cold chamber machines are suited for aluminium die casting, parts on the machine (shot sleeve, plunger tip) can be replaced over time, sleeves can be metal treated to increase their durability. Aluminium alloy is melted in a ceramic crucible due to aluminium’s relative high melting point and the need to reduce the risk of iron pickup which is a risk within ferrous crucibles. Because aluminium is a relatively light metal alloy it affords casting of large and heavy die castings or where increased strength and lightness in die castings is required.