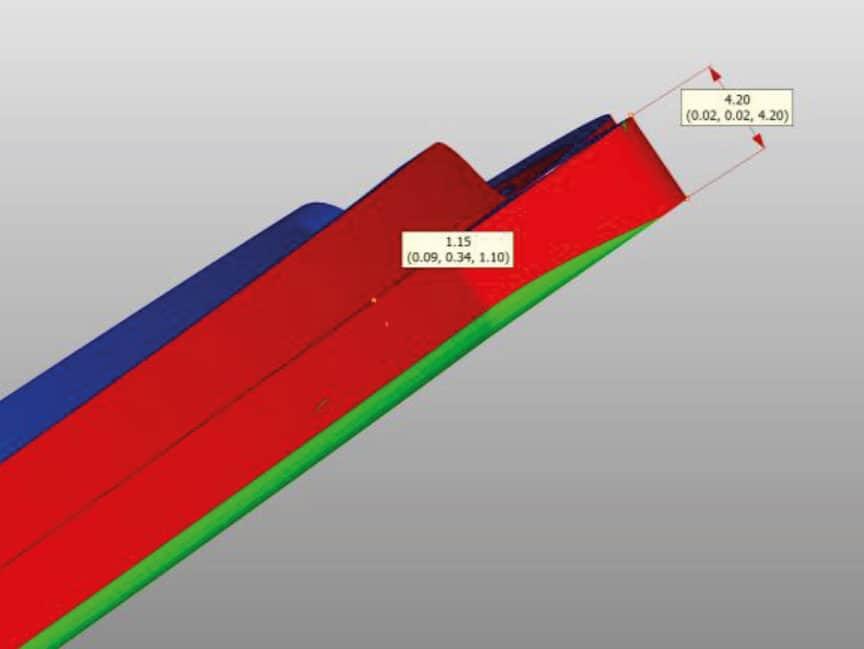

Our experienced engineers assess and analyse casting designs provided for tool manufacture taking into consideration Design for Manufacture (DFM) and Design for Assembly (DFA) principles conducting Finite Element

Analysis (FEA) to ensure we provide the optimum castings and tool design for our customer requirements.

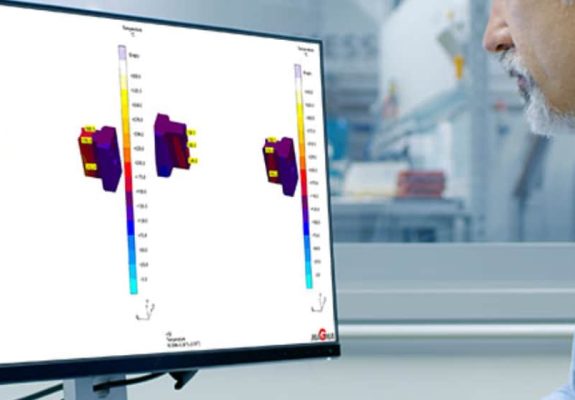

We utilise the latest iteration of Magma mould flow software to virtually simulate on a computer every element which can impact on the forming of a die casting to eliminate possible weaknesses including but not limited to:

This process in turn provides the following benefits where it can be achieved:

We believe a collaborative approach with our customers is beneficial to provide the best production conditions for manufacturing and assembly ensuring quality of our aluminium and zinc pressure die castings and providing optimum tool life.

We utilise an industry experienced design team operational 24/7 on split shifts utilising the latest software:

With the input of our industry expertise utilising the latest software technologies at our disposal we can thoroughly analyse and design out potential issues before our tool manufacture commences.