Our design team operate on split shifts 24/7 utilising the latest software working with compatible formats for the software listed as well as industry standard IGES/STEP (3D), DXF/DWG (2D) files to design die mould or pattern tools, clip/press tools and CNC machining jigs and fixtures:

Our design team can also design products and prototypes utilising our extensive die casting experience in both design and production with our in-house CNC machine shop able to machine the finished product.

We work on the philosophy that the die design should minimise and reduce the cost impact to the customer for secondary processing of components after they have been cast whilst providing optimum output from the tools.

The quality of the casting and subsequent tool design is a result of our extensive DFM, DFA and FEA process early in a projects life cycle assessing aspects such as:

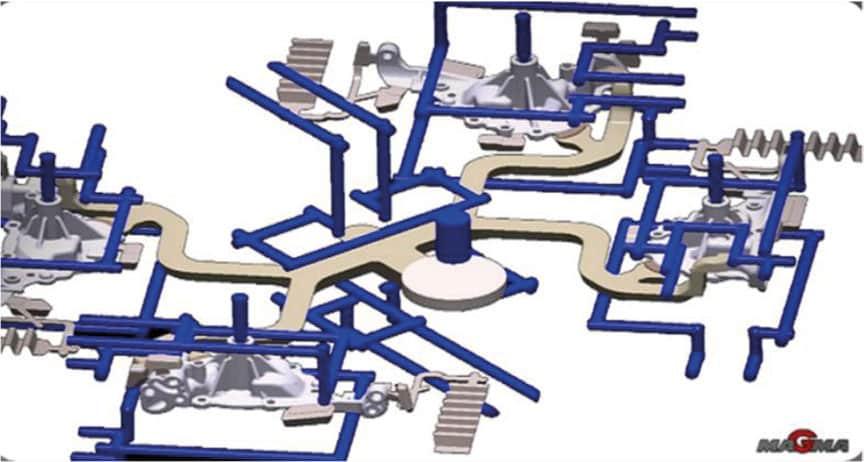

Our design team utilise the latest industry software such as Magma mould flow to virtually simulate on a computer all aspects of the production casting cycle to optimise the process quality of the castings and providing optimal tool life. MPD will provide recommendations to the casting design to benefit the production process as well as the assembly process for the customer where benefits can be gained.

After the extensive pre-design analysis of the casting design and Magma mould flow simulation our design team will provide the best layout and tool configurations to ensure easy maintenance of the tool throughout production which MPD believe should not impact the customer.

This extensive and invaluable process is carried out prior to machining tool steel for tool manufacture ensuring a smooth project workflow from start to finish.